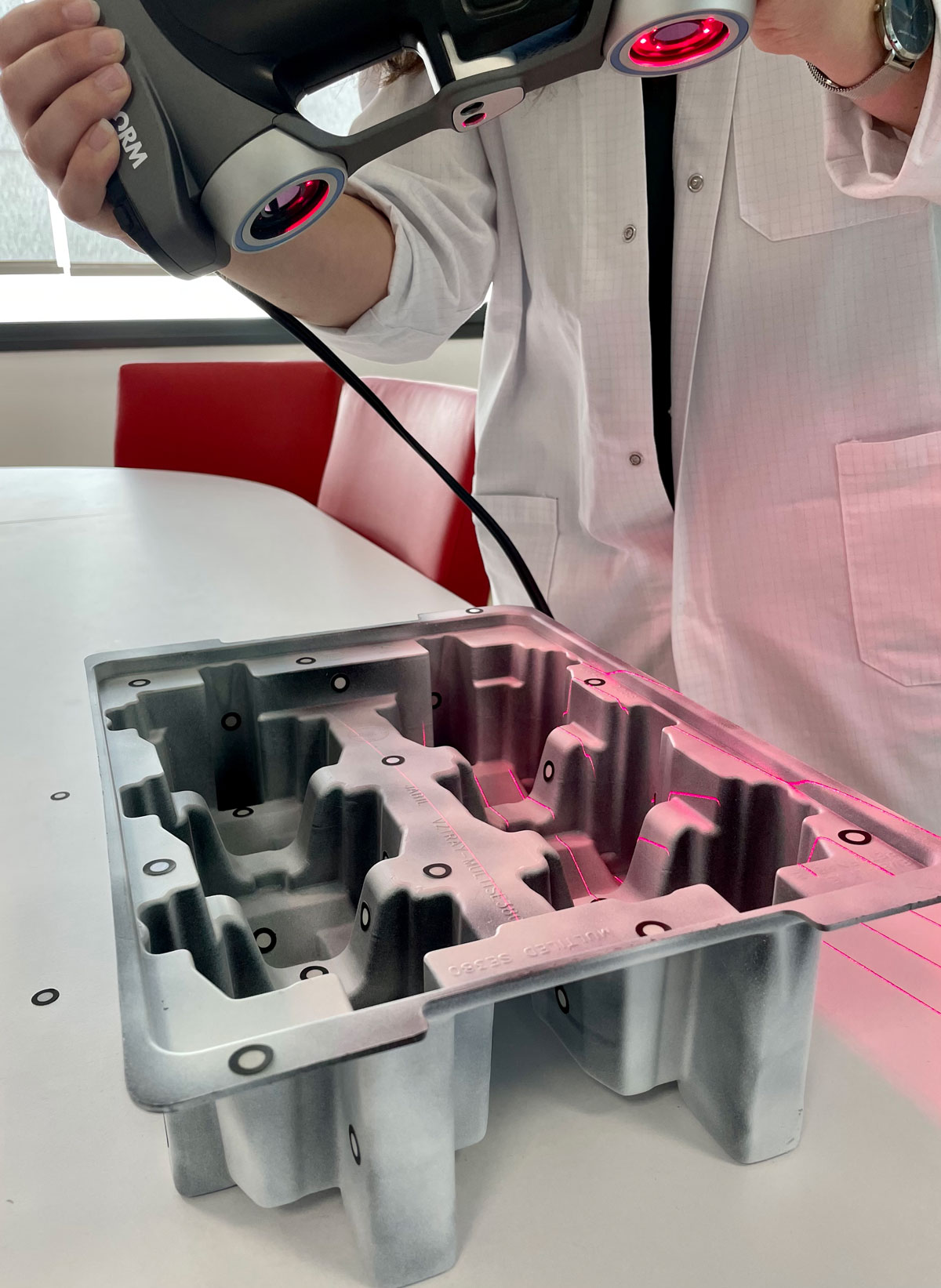

IMD/PMD

Insert molding decoration & Print mold design.

La demanda de componentes de plástico solido y ensamblados a la perfección con geometrías irregulares y de alta complejidad es habitual en el sector de la automoción. Para la producción de estas piezas a partir de materiales de alta calidad, texturas y diseños novedosos se hacen necesarias varias fases: hot stamping, thermoforming with vacuum and pressure, punching (if necessary) and high precision cutting.

The results are plastic components that are creatively designed and precisely drilled into their final shape, which can be easily integrated into final products.